Thanks to the forward thinking and sheer daring of our founders, sustainability, fuel efficiency and innovation have been a driving force right from the outset.

State-of-the-art from the start

The origins of our company are to be found in the late 1970s, when there was a growing demand for flexible and economic regional air connectivity that jets couldn’t meet. Thinking outside the box and completely independently of each other, France’s Aérospatiale and Italy’s Aeritalia each launched the design phase of a state-of-the-art turboprop aircraft.

In a wonderful example of cross-border cooperation, Aérospatiale and Aeritalia realised they had a common ambition and put their heads together to create a single company: ATR, for Avions de transport regional or Aerei da trasporto regionale (‘regional transport aircraft’ in French and Italian respectively). Their first brainchild was the ATR 42-300, a 42-seater that combined the most innovative aspects of its founding companies’ designs – aspects that are still a hallmark of ATRs and some of the keys to their success!

High wings and sawmills

To start with, the 42-300’s high wings enabled the engines and propellers to be placed high off the ground. This made it possible to increase the diameter of the propellers and consequently propeller efficiency, while limiting the impact of debris projected from untarmacked runways and facilitating freight loading.

Its T-tail ensured the aerodynamic efficiency of the Horizontal Tail Plane, while the low undercarriage was designed both for robustness and airframe efficiency and because it enabled the aircraft, with its high wings and short wheel track, to take off and land on very narrow runways.

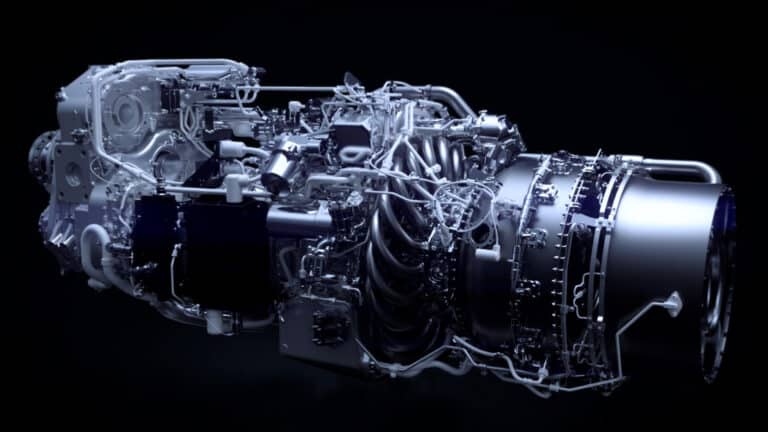

Another key feature which contributed to ATR’s success was the positively inspired choice of engine. Pratt & Whitney’s PW100 had proved its worth, not on aircraft but in the huge sawmills of Canada’s frozen North! Fitted with propellers and adapted specifically for the 42-300, the company’s new PW120 could reach speeds of up to 550km/h (300nm/h) and boasted sustainability and reliability levels second to none. Since those early days, this close collaboration between ATR and Pratt & Whitney has gone from strength to strength, culminating in the recent launch of the PW127XT-M engine, purpose-built for both the ATR 42 and the ATR 72.

‘Hotel’ mode

Right from the outset, ATR aircraft have featured an exclusive ‘hotel’ mode that remains unique to this day. In-between flights, aircraft require energy for cabin heating, air conditioning and lighting, cockpit preparations and restarting the engines for take-off. Most get this energy from either an onboard auxiliary power unit (APU) or a ground-based power unit (GPU). But while APUs are expensive, heavy and costly to maintain, GPUs require a certain level of airport infrastructure.

ATR aircraft generate the power required by running the right-hand engine at low speed, with a brake on the propeller. It’s a simple yet ingenious solution that enables ATR aircraft to remain both light and autonomous.

Composites

Even the very first ATR, the 42-300 launched in 1984, placed great emphasis on the use of composites, something that was practically unheard of at the time! ATRs were the first turboprops to feature composite propellers, and in 1988 the ATR 72 became the world’s first civil aircraft with a carbon-fibre outer wing box.

Today’s ATR aircraft incorporate a range of lightweight sandwich composites in both their primary and secondary structures (wing, tail, nose, propeller blades, brakes, cabin, etc.), using a range of skins such as glass, Kevlar and carbon. This explains why ATR aircraft have the lightest airframe anywhere for this size of aircraft, which contributes to their low carbon footprint.

Unbeatable flexibility

One of ATR aircraft’s abiding qualities is their incredible flexibility and their ability to safely take off and land almost anywhere, regardless of airport location, runway length or available ground systems, thanks to their Localizer Performance With Vertical Guidance (LPV) and Vertical Navigation (VNAV) avionics features. This has enabled our customers to establish routes to places that would otherwise only be accessible via long and perilous road or boat journeys. ATR continues to push the boundaries in this area, as evidenced in its more recent development of RNP AR 0.3/0/3.

ATR remains committed to shaping the future of regional aviation responsibly.

Check out our latest innovations!