What is a turboprop?

A turboprop aircraft is a type of aircraft powered by a propulsion system that combines a gas turbine engine with a propeller. An aircraft engine is the beating heart of the plane, it’s where energy is transformed into thrust or traction force. In turboprops, this energy is used to rotate a propeller.

One of the key strengths of turboprops is their exceptional fuel efficiency at lower speeds and altitudes, making them the ideal choice on regional routes. They consume significantly less fuel than similar-size jets, which reduces operational costs as well as environmental impact.

The turboprop aircraft versatility allows them to operate and access a wide range of airfield profiles: from short runways to unpaved ones, in extreme weather conditions and high crosswinds; making them the ideal choice for regional and commuter aircraft. In fact, an impressive statistic reveals that approximately 34% of airports globally rely exclusively on aircraft equipped with turboprop engines for their operations.

Modern jet engines, used on most airliners today, are increasingly incorporating design features that make them resemble turboprops. Their high bypass ratio means that most of the air entering the engine bypasses the combustion chamber and is pushed backwards by the large front fan, which pushes air around the engine much like a propeller. To make them even more efficient, some of the newest designs also use a gearbox that lets the fan and engine low pressure pool spin at their best possible speed, just like the reduction gearbox in a turboprop.

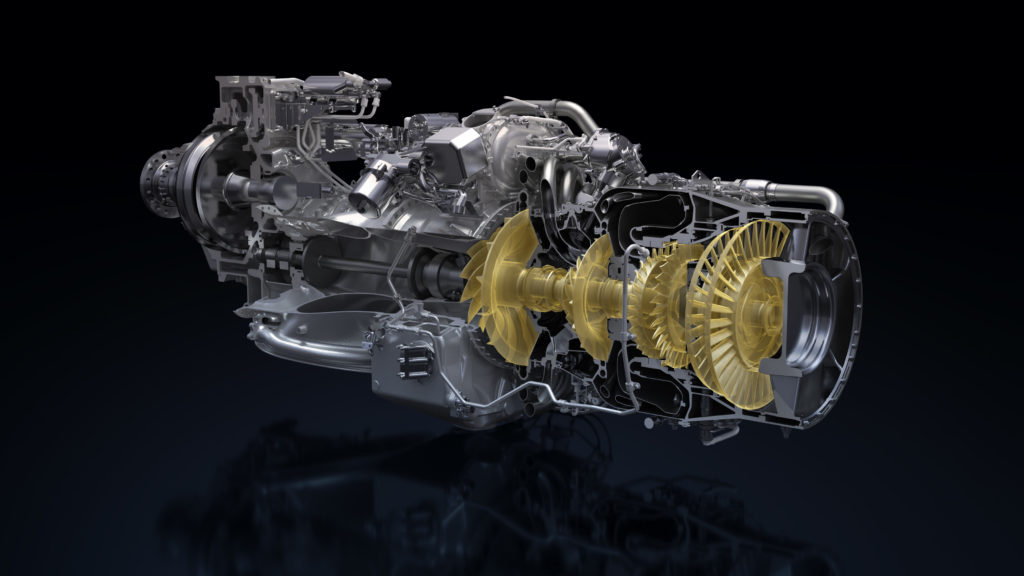

Turboprop Engine

A turboprop engine operates on the principles of gas turbine propulsion and is commonly used in regional aircraft. Turboprop engines rely on turbines to convert energy from oil combustion into mechanical movement.

How does a turboprop engine work?

- Air Intake: The process begins as the engine draws in ambient air through an intake.

- Compression: The incoming air is compressed by a series of axial or centrifugal compressors to reach optimum pressure and temperature before being burnt with fuel in the combustion chamber.

- Combustion: Aviation fuel is injected into the high pressure, compressed air and ignited. This combustion process produces high-temperature, high-pressure gases.

- Gas Expansion: The rapidly expanding gases flow through a set of turbines. These turbines are connected to the compressor and power the entire engine cycle.

- Power Shaft: the power generated by the turbines in a turboprop transferred to a power shaft.

- Reduction Gearbox: The power shaft connects to a reduction gearbox, which reduces the high– speed rotation of the turbine to a suitable speed for the propeller shaft. The power turbine is crucial in driving the propeller, while the gearbox reduces the turbine’s very high rotational speed (approx 20,000RPM) to a level suitable for the propeller (Approx 1,200RPM). This reduction prevents the blade tips from reaching supersonic speeds, ensuring both efficiency and lower noise.

- Propeller pitch: By changing propeller blade angle, the turboprop engines optimise performance for takeoff, cruise, or landing.

- Propeller: The propeller shaft drives a multi blade propeller at the front of the engine. Because of propeller blade curved airfoil, the rotation speed of the propeller generates a forward aerodynamic force called ‘traction’

The development of advanced materials and technological innovations continues to enhance the efficiency and safety of turboprop propulsion systems. Advancements in digital engine control systems have further improved the efficiency of modern turboprop engines, optimising fuel-air mixtures in real-time. Some new generation turboprop engines will incorporate hybrid-electric propulsion systems, reducing emissions and improving overall sustainability.

Turboprop aircraft: what are they used for?

The versatility of modern turboprop aircraft underscores their exceptional design and adaptability. Originally conceived as efficient regional passenger aircraft, turboprop aircraft have evolved to cater to a diverse range of aviation needs. Their modular design allows for swift transformations, enabling these aircraft to effortlessly transition from serving as passenger carriers to efficiently transporting cargo, offering a high degree of operational flexibility and cost efficiency.

ATR turboprop aircraft exemplify this adaptability and even offer a greater operational flexibility with the passenger-cargo “combi” version of the ATR 72-600, that allows operators to carry both passengers and cargo simultaneously, optimising capacity and meeting varied market needs.

They can even accommodate VIP configurations like ATR HighLine, ATR’s collection of high-end cabin interiors dedicated to air carriers seeking an unparalleled experience for guests. ATR’s commitment to versatility ensures that operators have the flexibility to tailor their fleets to dynamic market demands, offering a cost-effective solution for regional airlines, cargo operators, and other types of carriers. This adaptability not only underscores the economic viability of ATR aircraft but also positions them as a reliable choice across a spectrum of aviation requirements, showcasing the brand’s commitment to innovation and meeting the evolving needs of the aviation industry.

Advantages of Turboprop Planes

Turboprop aircraft offer several advantages:

- Fuel Efficiency: Consuming significantly less fuel than jet engines, turboprops provide a cost-effective alternative for regional flights.

- Lower Operating Costs: Maintenance and operational expenses are generally lower compared to jet-powered aircraft.

- Versatility: Their ability to operate on shorter runways increases accessibility to regional and remote airports.

- Environmental Benefits: Turboprop aircraft are among the most fuel-efficient airplanes, consuming less fuel than comparable turbofan-powered aircraft. This results in lower CO₂ emissions and reduced operating costs. In addition, turboprops typically cruise at lower altitudes, where they avoid producing contrails. Thanks to their fuel efficiency and lower emissions, turboprops play an important role in advancing sustainable aviation solutions.

History

Turboprop technology dates to the mid-20th century, with the first successful engines developed in the 1940s. The concept of using a gas turbine to power a propeller was explored as an alternative to piston engines, which had limitations in terms of power output and efficiency. Early turboprop designs sought to combine the best features of jet and propeller propulsion, providing better fuel efficiency than early jet engines while maintaining the operational flexibility of piston-driven aircraft.

The earliest applications of turboprop engines were seen in both military and commercial aviation. The British-designed Rolls-Royce Dart, one of the first practical turboprop engines, was instrumental in advancing this technology. The Vickers Viscount, powered by Dart engines, became the first successful turboprop-powered commercial airliner, entering service in the 1950s. The Viscount demonstrated the advantages of turboprops over piston-driven aircraft, such as greater speed, higher passenger comfort, and improved fuel efficiency, leading to widespread adoption among regional carriers.

During the 1960s and 1970s, turboprop technology continued to evolve, with manufacturers developing more powerful and fuel-efficient engines. Advances in engine materials and aerodynamics further improved reliability and performance.

The 1980s and 1990s saw the introduction of modern turboprop models, including the ATR 42 and ATR 72, which set new benchmarks for fuel efficiency and operational flexibility. These aircraft were designed specifically for regional markets, catering to airlines seeking cost-effective solutions for short-haul travel. Innovations such as variable-pitch propellers, improved reduction gearboxes, and quieter engine designs enhanced passenger experience and operational performance.

This legacy of innovation continues with today’s new-generation ATR 42-600 and ATR 72-600, which are powered by Pratt & Whitney Canada’s advanced PW127XT engines. Representing the latest evolution in turboprop propulsion, the PW127XT delivers a 40% extension in time on wing, a 20% reduction in maintenance costs, and a 3% improvement in fuel efficiency compared to previous-generation engines.

Building on decades of proven performance, this engine family exemplifies how modern turboprops are combining cutting-edge technology with the fundamental strengths that have made them a mainstay of regional aviation for over half a century.

In recent decades, sustainability and technological advancements have shaped the future of turboprop engines. The incorporation of digital engine control systems has optimised fuel-air mixtures in real time, improving reliability and reducing emissions. With increasing focus on environmental sustainability, modern turboprops are being designed to operate on alternative fuels, including biofuels and synthetic aviation fuels. Research into hybrid-electric propulsion systems is also paving the way for even more fuel-efficient and low-emission turboprop aircraft.

Today, turboprop aircraft remain a crucial component of regional and short-haul aviation, bridging the gap between remote locations and major hubs. Their ability to operate on short and unpaved runways, along with their cost-effective operation, continues to make them a preferred choice for airlines looking to balance efficiency, performance, and environmental responsibility.

Throughout the decades, turboprop propulsion has evolved significantly. Advances in materials science have led to lighter, more durable components, improving both the lifespan and efficiency of modern turboprop engines. Additionally, enhancements in aerodynamic design, such as optimised propeller blade shapes and variable-pitch mechanisms, have significantly improved overall fuel efficiency and performance.

Another major development has been the incorporation of digital engine control systems, which optimise fuel-air mixtures in real time, improving reliability and reducing emissions. Sustainability focused innovations have also played a key role, with modern turboprops increasingly designed to use alternative fuels, including biofuels and synthetic aviation fuels. As global regulations push for reduced carbon footprints, ongoing research into hybrid-electric propulsion systems and low-emission alternatives continues to shape the future of turboprop technology.

Looking Ahead: The Turboprop Market Today and its Future in Aviation

As the aviation industry evolves, turboprops are poised to play a critical role in meeting growing demands for regional connectivity and low-emission flight solutions. According to the Turboprop Market Forecast 2025-2044, airlines will need approximately 2,100 new passenger turboprops and 500 freighter turboprops over the next two decades to replace aging fleets and support expanding route networks.

These aircraft offer a compelling path forward, not only do they enable service to remote or underserved regions (short or unpaved runways, extreme climates, etc…), they also help reduce carbon emissions, fuel consumption, and operational costs. As sustainability becomes imperative for both operators and regulators, turboprops emerge as one of the best solutions for balancing environmental responsibility with economic and social connectivity.